Maintenance is an important part of keeping a car safe, reliable, and performing at its best. Some components are designed to wear out. Others have a ‘life’ and the rest should go on and work for the lifetime of the vehicle.

Normally, it’s the parts that are the most difficult to reach or replace that are designed to last. Think of the crankshaft, pistons, and con-rods as an example. Whereas items such as brakes will wear out on a regular basis. But, that’s the nature of design and part of the way they work.

Modern Braking Systems

For the purpose of the article, we’re talking about hydraulic braking systems, using brake pads and discs (or rotors) to retard the vehicle. Drum brakes aren’t used often nowadays, even at the lower end of the budgetary scale. But, they can still be found on some new vehicles, usually at the back wheels. However, we can’t think of any vehicles that use drum style brakes all-round.

To understand why they wear, we should first look at how they work:

Usually, the brake disc is fitted to the wheel hub assembly. It rotates at the same speed as the wheel. To slow the vehicle down, a brake pad (or multiple pads) is forced onto the surface of the disc through a hydraulically operated piston within the brake caliper.

The brake pads are made from a friction material, allowing them to ‘grip’ the surface of the disc. This, in turn, slows down the vehicle. All quite simple stuff.

Depending on the vehicle, it may be possible to buy brake pads with different qualities. Some that last longer and some that operate better as they get hotter. And others that offer more braking power. But, all of these qualities come at a price.

The longer-lasting pads won’t offer the same level of braking power. The ones with the most power will often wear out quicker. And the ones that work better when hot, usually won’t be as efficient when cold.

What Is Brake Judder?

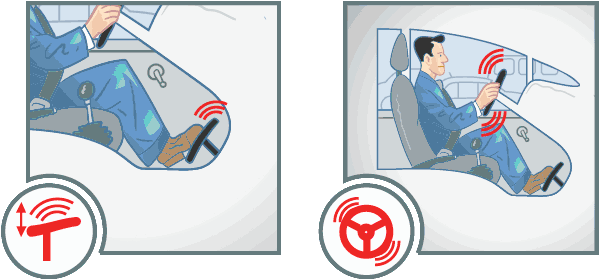

Brake judder usually happens when the brake disc has warped. It’s usually due to excessive heat. You’ll feel it through the brake pedal, and possibly through the steering wheel when applying the brakes. You’ll get a shuddering effect that can feel as though the whole car is running over a rippled road surface. As soon as you let your foot off the brake pedal, it will stop almost immediately.

Brake discs wear at a much slower rate than brake pads. But, they still do wear over time. And as they get thinner, they can’t dissipate the heat as efficiently. Prolonged hard breaking will lead to the problem being exacerbated.

A brake disc has an incredibly hard life. It has to cycle from cold to hot and back to cold without cracking, shrinking, warping or failing. And for those of you that know thermal dynamics, you’ll understand just how hard that can be.

Modern processes have helped the situation. A range of heat treatment is now available and newer designs have led to the minimization of warped brake discs. But, that’s on the newer cars. There are still millions of older cars on the roads, and they could all potentially suffer.

Fixing The Problem

Some people believe that brake judder can be cured through completing some hard braking maneuvers. Stopping in as shortest distance as possible from speed (60+ mph) a number of times. In other words, getting the discs as hot as possible and then letting them cool off naturally.

It’s certainly true that some metals can react well to heat treatment, usually acting as a stress-relief for the material. However, it’s very unlikely that you’ll ever straighten a brake disc in this manner.

The reality is that you’re going to need to change the discs. And it’s good practice to change the brake pads at the same time.

There are a number of things that you can do to try and help avoid brake problems such as this, but nothing to cure it once it has started.

Take a walk around any race paddock. There is a good chance that you’ll see a mechanic rotating the wheels once a car has come back into the paddock after a hot lap. This is purely to stop any heat spots building up on the brake discs from the brake pad, as it just sits there.

Equally, if you’re the type of driver that likes to ‘make progress’ on their daily drive, you should take note of how these teams take time to do a ‘cooling down’ lap. It allows for the drivetrain, engine, gearbox, and components to cool off a little before stopping.

It’s even more important to let your engine do the same, especially if you have a turbocharger fitted. (Turbo’s work at an impressively high rate of revolutions per minute, they need a constant oil feed until they’ve slowed down.)

Avoid braking unnecessarily hard for prolonged distances. Not only will this help with keeping your brakes cooler, but it will also help to maintain a smoother driving style. This, in turn, could also help with your fuel economy, tire longevity, and general reliability.

Brake Replacement

Replacing your brakes is a relatively simple and straightforward process. However, you should remember that if you get it wrong, you are potentially risking your life, along with other drivers. If you aren’t sure, you’re better off getting them done professionally.

Every car is different, but there are some basic principles that can be applied to all of them.

- Loosen the wheel nuts before jacking the car up – the weight & brakes of the car should be enough to hold the car steadfast for the initial loosening.

- Jack the car to a safe working height, use jack stands (not bricks or wood) to support it.

- Remove the road wheels, visually inspect the brakes – pads & discs.

- You will normally need to remove the caliper completely. However, in most cases, you can leave the rubber brake line attached if you can support the caliper so that it isn’t hanging on the brake line.

- Remove the caliper carrying bracket to allow full access to the brake disc.

- Brake discs are generally held on with a single small screw, be sure to get the right fit screwdriver or Torx bit to undo it – if you damage the head of the screw and can’t remove it, your job has got a lot more difficult.

- Ensure that all mounting surfaces and locating pins are clean and debris free – the brake disc needs to sit perfectly flat.

- New brake discs come with a rustproof coating, ensure that you clean it off thoroughly before coming into contact with the brake pad, use a solvent such as a brake cleaner.

- Threadlock adhesive is a sensible choice for the caliper carrier bolts, and caliper itself.

- Ensure that if the caliper is meant to move (a ‘floating’ caliper), that all surfaces, pins, and rubbers are in good condition, preferably with an appropriate lubricant like Copaslip.

Once you have fitted the new discs and pads, you will need to bed them in gently. Your braking system will not operate at full efficiency for some miles, so plan your braking and try to avoid a situation that leads to you needing to brake sharply.